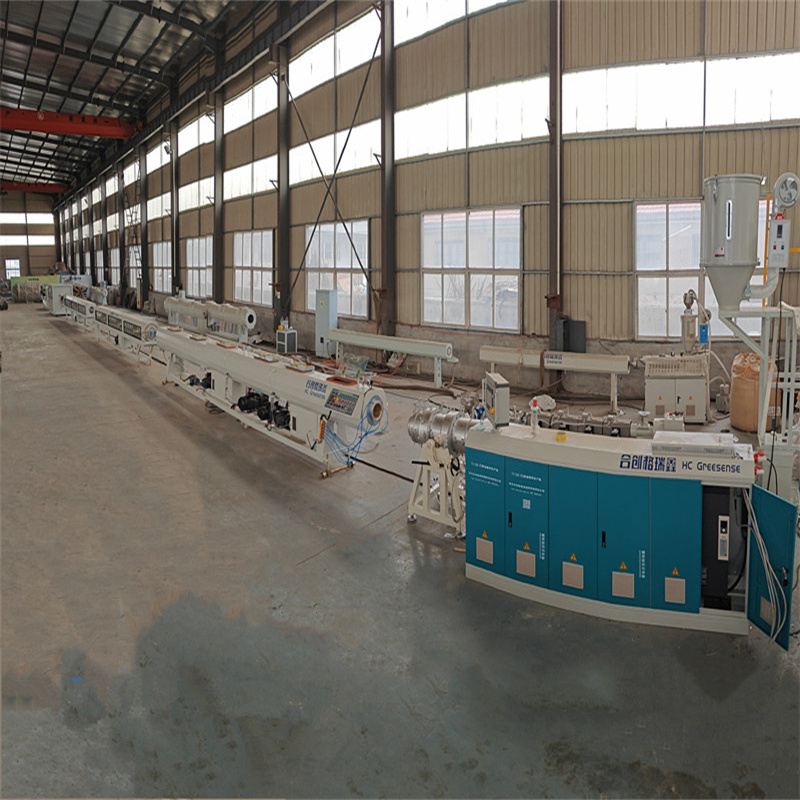

Пластикалық құбырды экструдер машинасы

Сұрау жіберу

Below are the main types of pipe extrusion equipment provided by COMRISE MACHINERY and their features:

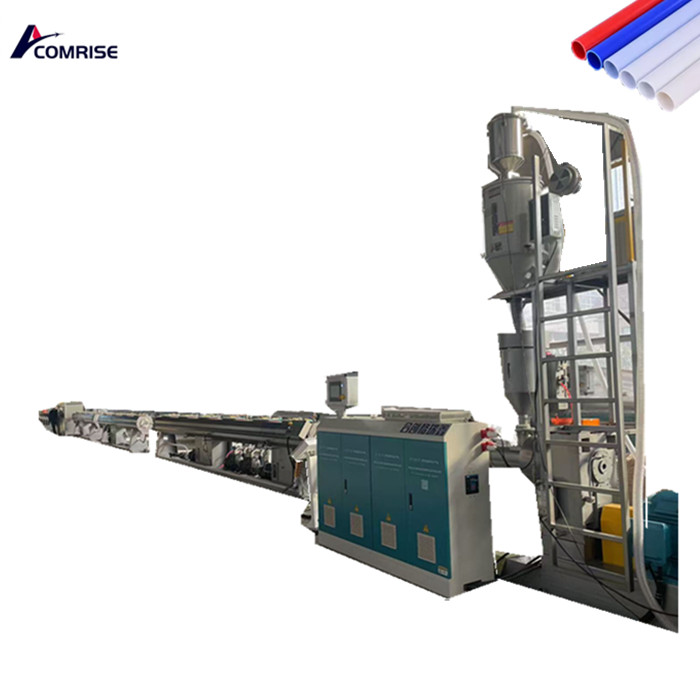

1. PVC Pipe Extrusion Line

- Applications: Used for producing rigid PVC pipes, such as water supply pipes, drainage pipes, and electrical conduits.

- Features:

- High-efficiency extruder for stable melting and extrusion.

- Precision die design ensures uniform pipe dimensions and wall thickness.

- Rapid cooling system enhances production efficiency.

- Automated control system simplifies operation and reduces manual intervention.

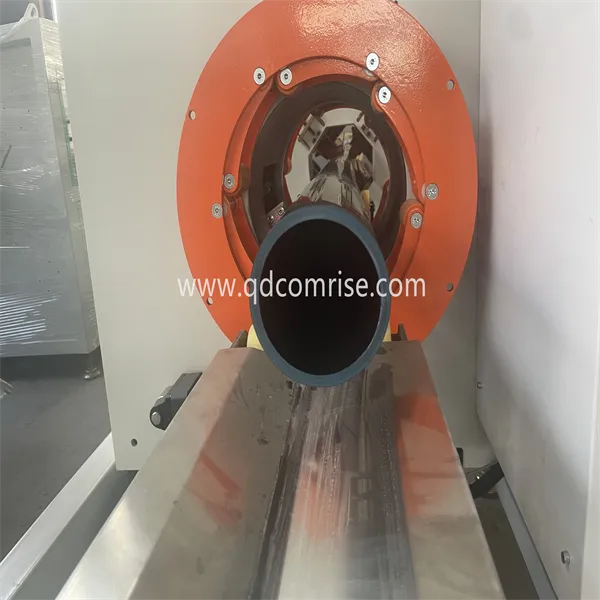

2. HDPE Pipe Extrusion Line

- Applications: Used for producing high-density polyethylene (HDPE) pipes, such as gas pipes, water supply pipes, and underfloor heating pipes.

- Features:

- High-torque extruder suitable for the high viscosity of HDPE materials.

- Advanced vacuum calibration and water cooling systems ensure high precision and smooth surface finish.

- High-pull-force haul-off unit for large-diameter pipe production.

- Modular design for easy maintenance and upgrades.

3. PPR Pipe Extrusion Line

- Applications: Used for producing polypropylene random copolymer (PPR) pipes, mainly for hot and cold water systems.

- Features:

- Special screw design optimized for PPR material plastification.

- High-precision die ensures smooth inner and outer pipe surfaces.

- Efficient cooling system shortens production cycles.

- Automated cutting and stacking systems improve production efficiency.

GET A QUOTATION NOW

4. Multi-layer Composite Pipe Extrusion Line

Used for producing multi-layer composite pipes, such as aluminum-plastic composite pipes and PE-RT composite pipes.

Features:

- Multiple extruders work together for co-extrusion of different layers.

- Precision die and calibration systems ensure uniform bonding of layers.

- High-precision control system guarantees consistent performance of composite pipes.

- Suitable for demanding applications like underfloor heating and gas transmission.

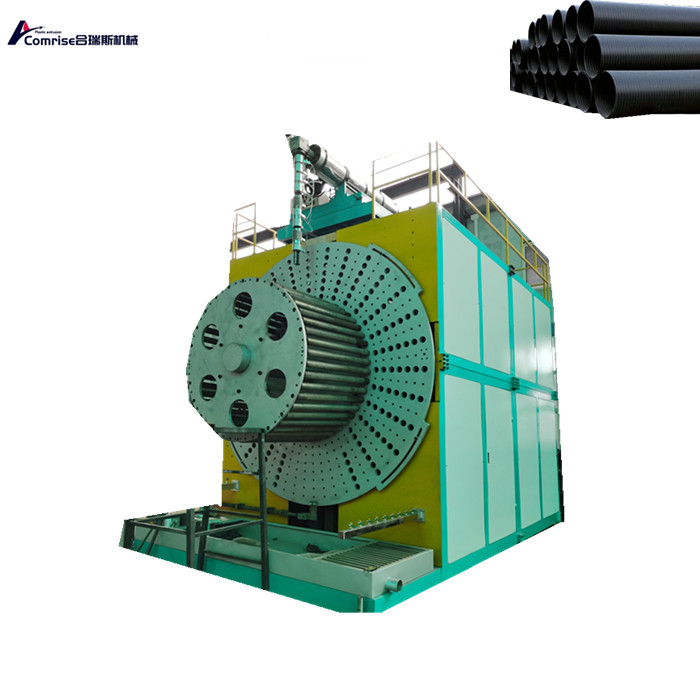

5. Corrugated Pipe Extrusion Line

- Applications: Used for producing single-wall or double-wall corrugated pipes, widely used in drainage and cable protection.

- Features:

- Modular design adaptable to different corrugated pipe specifications.

- Efficient forming modules ensure uniform corrugation structure.

- Rapid cooling system enhances production efficiency.

- Automated cutting and coiling systems reduce manual operations.

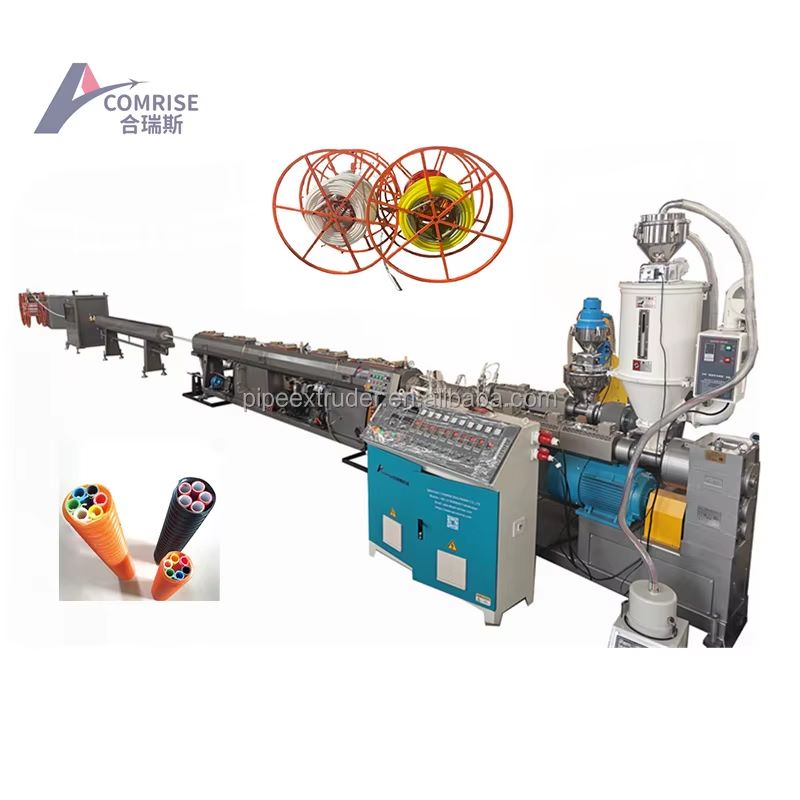

6. Silicone Core Pipe Extrusion Line

- Applications: Plastic Pipe Extruder Machine Used for producing silicone core pipes, mainly for optical cable protection.

- Features:

- Plastic Pipe Extruder Machine Dedicated extruder designed for the special requirements of silicone core materials.

- Plastic Pipe Extruder Machine High-precision die ensures smooth inner walls, reducing friction.

- Plastic Pipe Extruder Machine Automated control system guarantees high-quality pipe production.

- Efficient cooling and haul-off systems improve production efficiency.

Advantages of COMRISE MACHINERY Plastic Pipe Extruder Machine

1. Advanced Technology: Incorporates internationally leading Plastic Pipe Extruder Machine technologies and control systems to ensure high performance and stability.

2. Customization: Provides tailored solutions to meet specific customer requirements for various applications.

3. Energy Efficiency: Plastic Pipe Extruder Machine designed with energy-saving features to reduce production costs.

4. Global Service: Offers comprehensive pre-sales, in-sales, and after-sales support to ensure customer satisfaction.

GET A QUOTATION NOW